It has been experimentally proven that tio 2 layers led to a higher and more stable flux of ceramic membrane under uv light through enhanced membrane wettability mendret et al 2013.

Flux ceramic membrane.

Nuclear membranes which cover a cell nucleus.

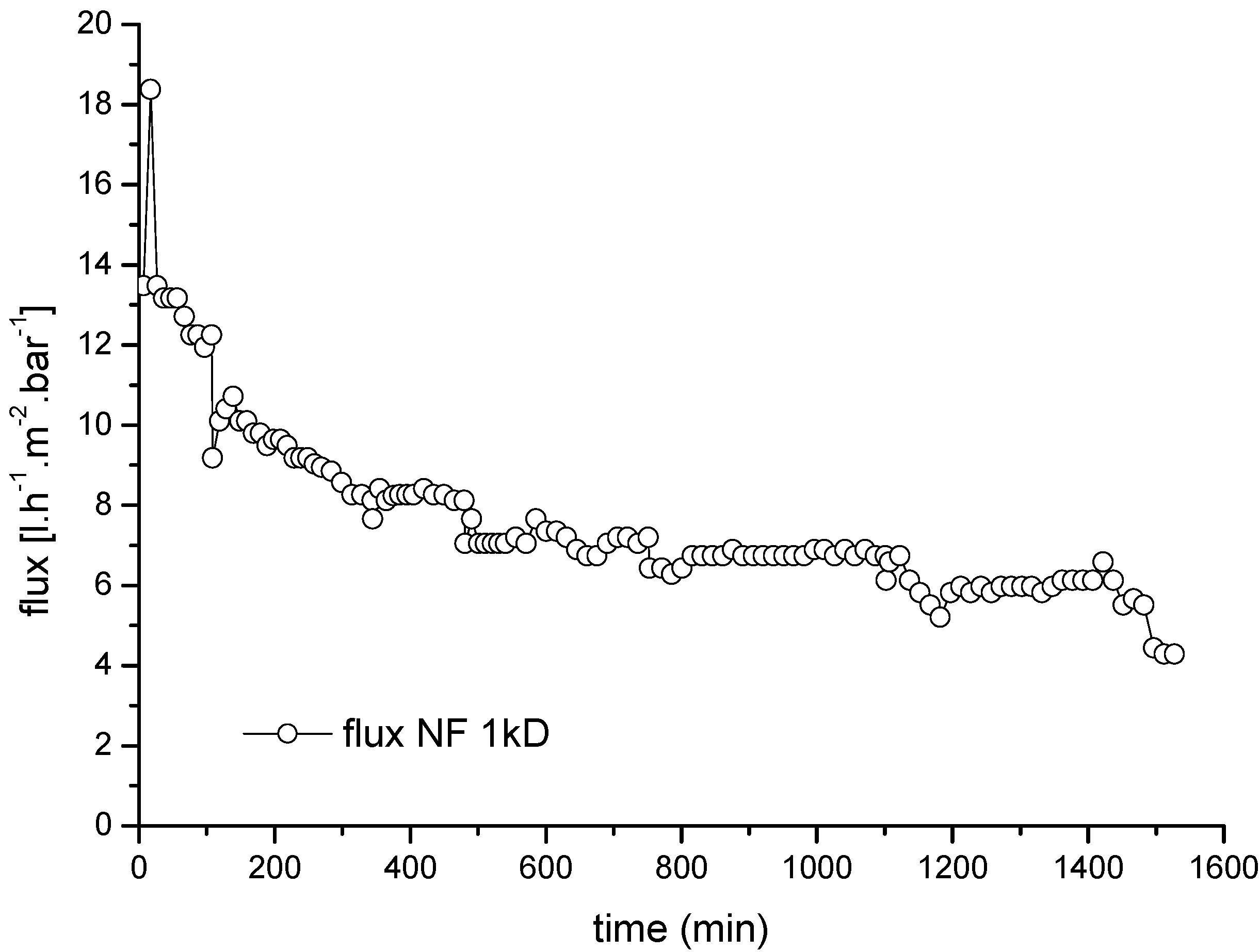

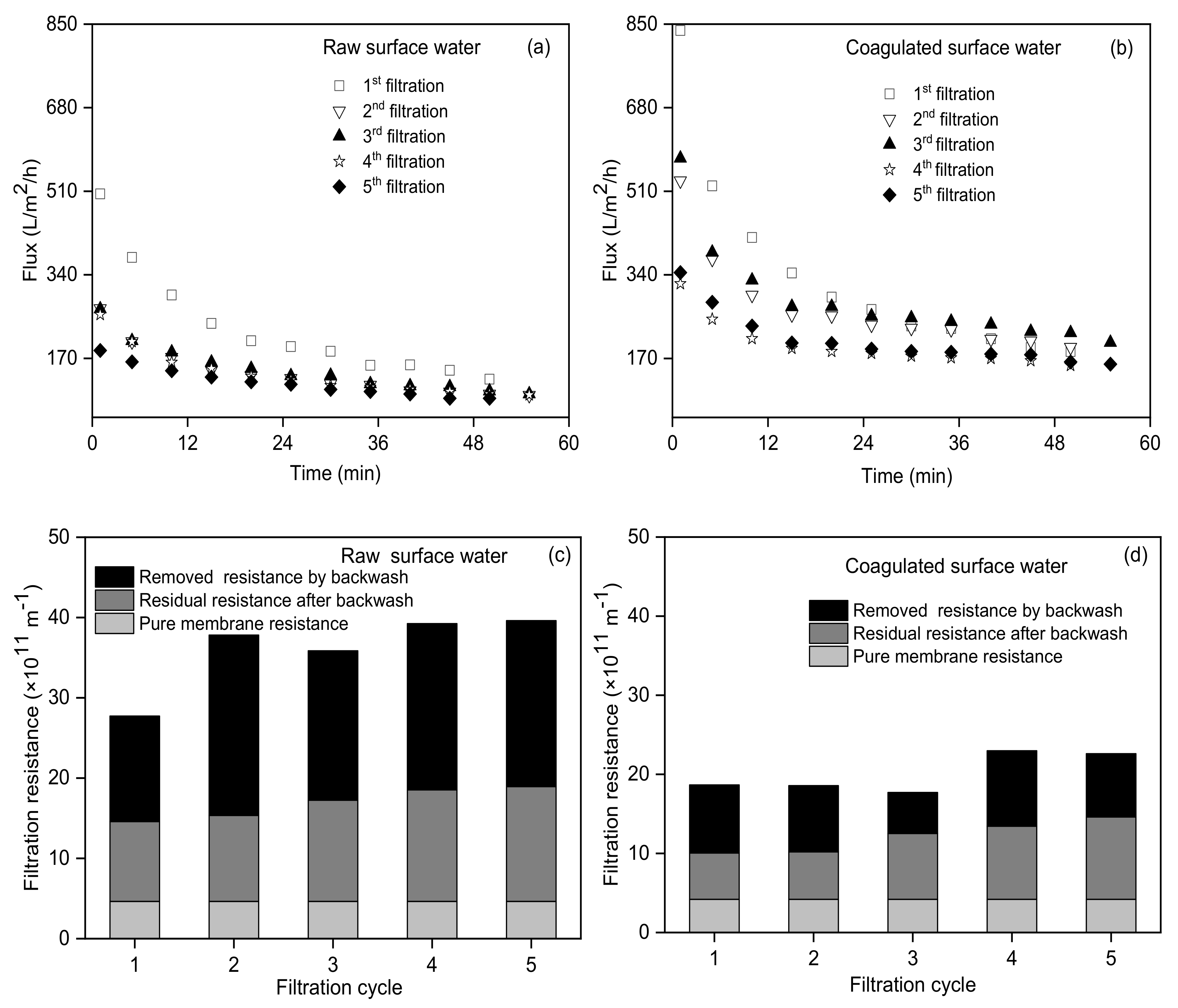

We can see a fast decrease during the first minutes of the test then it goes on decreasing slowly.

Biological membranes include cell membranes outer coverings of cells or organelles that allow passage of certain constituents.

The stream with fine process particles sio 2 and particles formed in the reaction manganese is then filtrated out with immersed ceramic silicon carbide sic flat sheet membranes with pore size of 0 1 µm ultrafiltration without using any flocculant the filtration step insures a stable operation and prevents fouling of the downflow reverse osmosis plant.

Ceramic membranes are a type of artificial membranes made from inorganic materials such as alumina titania zirconia oxides silicon carbide or some glassy materials.

Ceramic membranes are more attractive for use as photocatalyst supports due to their robust nature against chemical attack than polymeric membranes.

It allows some things to pass through but stops others.

The required membrane surface area is a function of the membrane flux and hydraulic load.

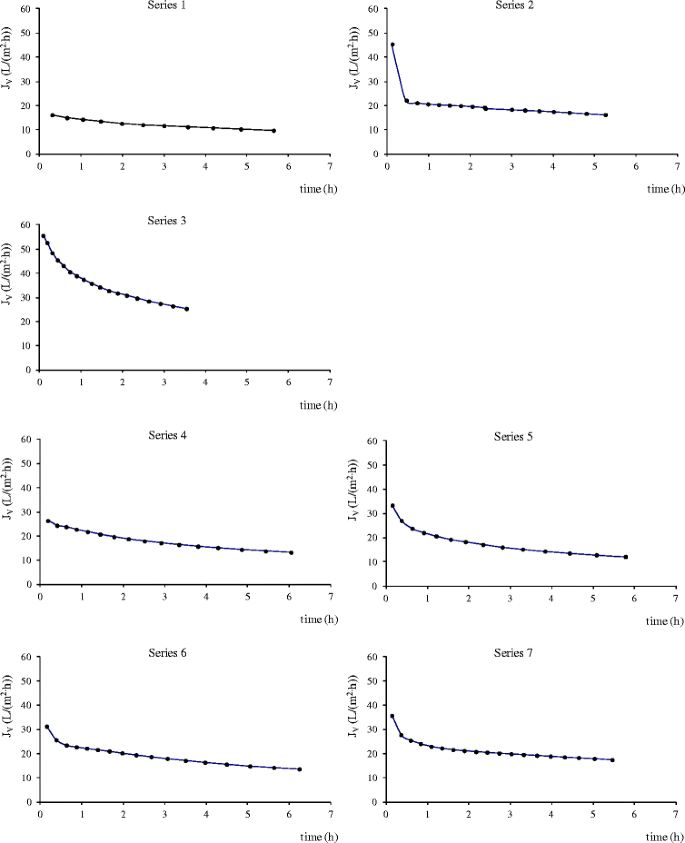

This decrease in flux profile is evident for all proteins solutions.

And tissue membranes such as mucosae and serosae.

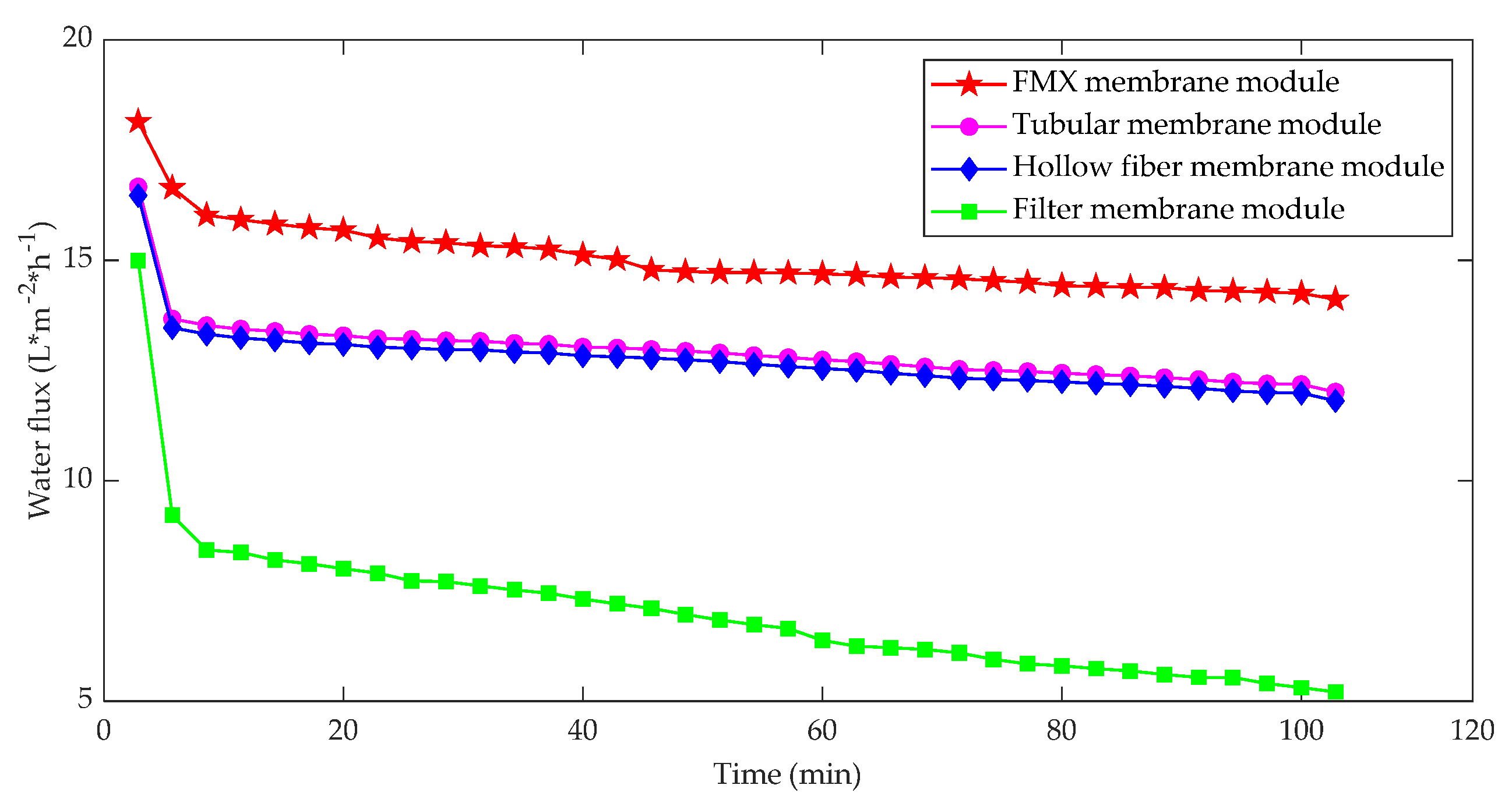

Stability of the filtration regime.

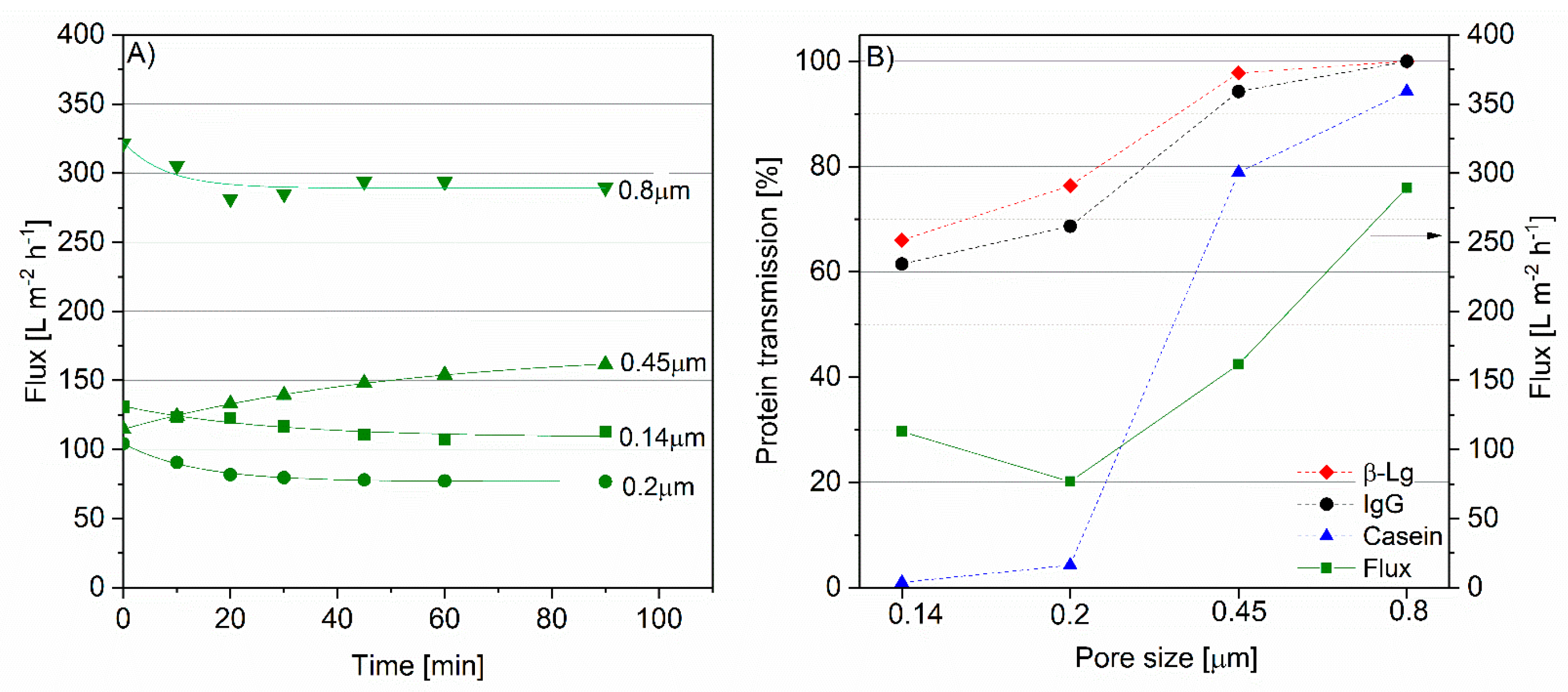

This optimizes the microfiltration of complex transmission sensitive feed streams.

Design features similar to the existing ceramem ceramic membrane offering the silicon carbide membranes are also suited to high operating temperatures above 150 c and have a high membrane element.

Tang in membrane based salinity gradient processes for water treatment and power generation 2018.

Membralox gp ceramic microfiltration membranes the membralox gp range of ceramic membrane elements have a calibrated longitudinal permeability gradient that maintains a constant and uniform flux along all parts of the element.

7 shows proteins solution flux through the ceramic uf membrane at a pressure of 0 3 bar as a function of time.

A membrane is a selective barrier.

To overcome the key issues of conventional membrane separation e g high energy consumption low flux and membrane fouling we designed a sandwiched α al 2 o 3 cofe 2 o 4 catalytic ceramic membrane structure highly efficient coupling membrane separation with catalytic degradation which exhibits a great potential for removal of mb and.

The net flux is an important parameter that characterises the average flow rate including the relaxation and backwash phases li fane ho matsuura 2008 with the help of net flux the treatment capacity of the whole plant is estimated.

By contrast with polymeric membranes they can be used in separations where aggressive media acids strong solvents are present.

It is found that the measured flux values are small compared.

Such things may be molecules ions or other small particles.

Most ceramic membranes are made of alumina titania silica zirconia or mixture of these materials 93 the basic structure of ceramic membranes consists of a macroporous support layer and meso or microporous active layer.